Uni-Solar v. Crystalline: A Primer

Right now the types of photovoltaics (PV) are limited to crystalline, polycrystalline and amorphous silicon. Without getting too technical, here's a quick primer on the differences.

The first two use silicon cells (a.k.a. semi-conductor chips) that require glass as the transparent rigid medium which holds the cells in place and protects them from the elements. Polycrystalline cells are ground or fragmented silicon cells (often surplus from the electronics or aerospace industries) mounted in glass. Silicon cells respond mostly to infrared and red light prevalent in mid-day sun from say 10 a.m. to 2 p.m.

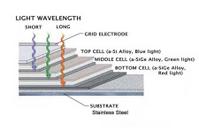

Uni-Solar PV is amorphous silicon, comprised of indium tin oxide (a transparent metal!), germanium, zinc oxide and silver on a

substreet (backing) of stainless steel. Arranged in layers, these components comprise Uni-Solar's triple-junction technology. They produce not only from infrared/red light but also the blue band (mornings) and green band (evenings) of the spectrum. Thus, by beginning to produce earlier and later, Uni-Solar cells can produce more energy per rated watt than its crystalline competitors--as much as 20% more. The adjoining pictures show newly-made Uni-Solar continuous

substreet (backing) of stainless steel. Arranged in layers, these components comprise Uni-Solar's triple-junction technology. They produce not only from infrared/red light but also the blue band (mornings) and green band (evenings) of the spectrum. Thus, by beginning to produce earlier and later, Uni-Solar cells can produce more energy per rated watt than its crystalline competitors--as much as 20% more. The adjoining pictures show newly-made Uni-Solar continuous  thin-film cells; the other shows a polycrystalline cell (left) and a crystalline cell. (Click any graphic for a larger view.)

thin-film cells; the other shows a polycrystalline cell (left) and a crystalline cell. (Click any graphic for a larger view.)Other Differences

Form: Standard silicon cells--with rare exceptions--come as framed modules that sit on racks on a roof or ground mount. They weigh four pounds or more per square foot installed. Uni-Solar offers framed modules, PV laminates for steel seam roofs and solar shingles that simulate composite shingles. Uni-Solar framed modules weigh about two pounds per square foot installed; laminates and shingles just 7/10 of a pound.

Durability: Standard cells use tempered glass which is pretty strong but can be heavy and breakable. Uni-Solar cells are encapsulated in a transparent teflon and are just 1/8 inch thick. Durable but not brittle they are simply unbreakable.

Affects of Heat: In heat extremes, glass modules can absorb heat that has an adverse affect on the silicon cells' performance; as much as 23% less production during extended periods of hot sunlight. However, Uni-Solar's thin-film cells run cooler and an average of just 3% efficiency is lost in extreme heat.

Cloudiness & Shading: Uni-Solar's wider spectral response to the sun's light makes it a good choice for less sunny climes or coastal areas affected by marine layers. As for shading a recent article in Mother Earth News explains it well: "For crystalline PV, electricity production is more affected by shadows; when just one cell is shaded, it blocks the flow of all electricity in that series. UniSolar amorphous PV transfers electricity using a weblike series of connections that bypasses shaded areas. (See "Crystalline v. Amorphous Silicon" link at right for full article.)

Versatility: As featured in the previous two posts in this blog, Uni-Solar offers true building-integrated photovoltaic options. If aesthetics are a must our PV laminates for metal roofs and solar shingles can't be beat for looks, low weight and toughness. If aesthetics aren't important then Uni-Solar framed modules perform better and weigh less than their silicon cousins without the worry of cracking or actual breakage.

Environmental Impact: All solar-powered energy reduces greenhouse emissions by not having to burn fossil fuels. What about the conventional energy that goes into making PV cells? It's a good question and hardcore environmentalists have used it to rap the PV industry. It takes about eight years for a standard silicon cell to produce as much energy as it took to produce it. It takes about a year and a half for a Uni-Solar cell to produce as much as it took in its production. Ideally, all cells will one day be produced by clean solar or wind energy resulting in zero emissions in the manufacturing process.

Have more questions or need pricing? Email me at dbrands@cox.net.

0 Comments:

Post a Comment

<< Home