Why Californians Are Going Solar

Solar power users aren't just a bunch of tree-huggers anymore.

Solar power users aren't just a bunch of tree-huggers anymore. This stems from the old adage "necessity is the mother of invention." Faced with higher energy bills and no end in sight, many ratepayers cut their consumption by updating to fluorescent light bulbs, purchasing more energy efficient appliances and adding better insulation to their houses. For most it just meant switching off lights when they weren't needed.

In a very short time after its "energy crisis" of 2000-2001, Californians became the most energy-efficient users in the nation. Did this reduce their energy costs? No, but conserving did seem to stave off increases since then. San Diego Gas & Electric uses a five-tier billing system with a baseline rate of 13.4 cents per kilowatt hour rising to 20.1 cents in the fifth tier. Basically, the more electricity used the more expensive it gets. To put this in perspective, most of the country averages about eight cents per kilowatt hour. So paying about twice as much as their neighbors in Arizona, solar becomes an option.

Upfront costs for photovoltaic systems (PV) are helped with incentives now offered by numerous states (see www.dsireusa.com). California offers both a rebate and an income tax credit for ratepayers tied to the big public utilities. New Jersey, New York and about a dozen other states offer various inducements as well.

Having sold Uni-Solar systems for three years now in the San Diego area, I've found the high cost of power coupled with the incentives make sense for moderate to heavy electricity users. Factoring in the potential annual increase of 4-5%, solar makes even more sense.

"The way I see it, I'd have to pay my electric bill no matter what it costs in the future," said an early customer who was financing his PV system. "But by purchasing solar, I divert most of what I'd pay to SDG&E to my bank for a system I will eventually own outright. Then I'll be generating free electricity."

While financial reasons are tantamount, there are others. Many ratepayers still resent the manipulation and greed to led to California's "energy crisis." Besides Enron, several other utility providers and brokers were complicit in the debacle. These are the "backlash" customers.

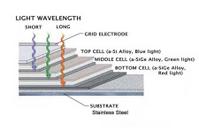

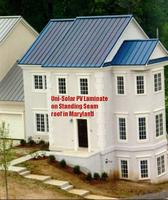

Other customers you could call the "tree-hugger" types but when you consider that one basic 2.5Kw PV system reduces annual greenhouse emissions by two tons, their actions are profound. Then there are those enamored with the technology. People with Uni-Solar laminates on their steel seam roofs or solar shingles on their composite roofs deserve some bragging rights. These are, after all, cutting edge PV applications.

Finally, there are those who simply believe going solar (or wind in the right areas) is the right thing to do. These homeowners are the select few who drive hybrids and have retrofit their homes to "green" standards. They don't preach; they lead by example.